Wednesday 29 April 2015

Tuesday 28 April 2015

Monday 27 April 2015

It has been a while!

I have had a busy week at work and my parents staying so have not been doing much on the car but I have improved some of the cooling pipe work, fitted the cowling, radiator front anti roll bar, oil cooler and roll bar. I have probably done a few other bits I can't remember.

I have also sent some questions to Derek as the oil system pipe work, diagram and sump don't align see photos below at tell me if you understand it

Sunday 19 April 2015

Sump protection

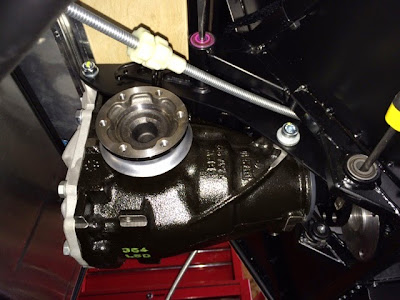

In a previous post I mention the gap between the bell housing and dry sump pan.

Having mention the hole, and sent a picture, to Derek, he sent the sump sump protector/hole blocker.

Saturday 18 April 2015

Questions about cooling

As the title suggests I have a few more questions. I have sent them to Derek and hope for a reply on Monday.

1. As I don't have a heater I have joined the water connection at the

rear right of the engine to a T piece. I have positioned this at the

water connection front left, just above the lower radiator pipe and

connected it to the smaller outlet. The third leg of the t piece joins

to the lower connection on the expansion tank. Is this all correct?

2. I have a short metal male male union with threaded boss (temp

sensor) half way along it. See photo. Do I need to put this in the

pipeline?

3. If it is needed which sensor is needed? See photo. I believe they

are for different garage types. If it is the one with the round

connection how does the connection work?

4. Again if it is the round type, will I need to use the same for the

oil temp sensor?

5. I think I have the wrong type of cowling. See photo. The fan is

significantly larger and the connections don't line up. Furthermore

the instructions talk of a front cowling as well as a rear. I have the

rear (but sigma) but no front.

6. I have connected the small water outlet at the rear of the engine

directly to the expansion tank is this correct?

I am sure this one is correct! But it is worth checking.

Tuesday 14 April 2015

Frustrating steering installation

This is definitely not the most annoying thing about this built, the shortages have been far more annoying but some how this has really got my back up.

Yesterday I followed the instructions and fitted the lower steering column. Over night I realised that, having torqued it up as per the documented request, I would need to remove the bottom of the lower column. This would allow me to set the orientation of the steering wheel. There are no other options with the quick release wheel. So again poor instructions.

So today I thought I would spend my precious evening fitting the upper column and wheel centralise it and torque it up for good. The points below outline the steps I took, try to see where I became frustrated.

1. Lubricate and insert top bush - easy

2. Grease upper column and slide through both top and bottom bush

- top bush bit of wiggling but ok

- bottom bush won't go through

3. Scratch head

4. Realise it is not the bottom bush but the lower column that it has to go over. (the lower column needs to slide inside the upper column and both slide inside the bush) It must be a bit misaligned.

5. As I will have to remove the clamp at the bottom of the lower column, I might as well do it now. I will be able to align them outside of the bush before sliding both in.

6. Slide out top column from bottom bush

7. Slide out lower column

8. Align and insert lower into outer.

9. Humm! It doesn't seem to fit.

10. Remove both from car.

11. Inspect upper - looks ok

12. Inspect lower - hum, it has a bit of a lip on it, probably form when it was parted.

13. No problem - out with file to remove lip.

14. It still doesn't fit - out with vernier

Inner diameter of upper

Huston we have a problem, or more specifically an interference fit. With a bit of heat I am sure I could get it in but it would never come apart again.

So rather than continuing to file, which would mean losing round ness and corrosion resistant coating I have decided I might let Derek send me a new lower.

Monday 13 April 2015

Prop to diff, primaries, catch tank and lower steering column.

I have done a few little bits over the last few days

Prop to diff

It was a bit fiddly but after a the first one I got the knack of it and the rest were easy. I put loctite on them all and torqued to 60 Nm

Next up was the primaries, but before fitting them I could not resist taking a picture down each exhaust port.

The only other thing I have now done is the lower steering column. (Sorry most of the photos are dark the lights in my garage are poor and most work is done in the evening.

Saturday 11 April 2015

Not without good reason

Not with out good reason.......is aligning, or rather inserting the top bolt in, the diff known as the hardest job. I nearly swaged three spacers in to the top LH bush, but after some precision engineering it is aligned to a the tightest tolerance the measurement uncertainty on my measuring instruments would allow. +-0.5 mm

For good measure I also removed the BMW shafts and stuck in the caterham ones

Friday 10 April 2015

Engine and diff

Sorry for not posting for a few days, I have been working on the car but Clare took the ipad and updating on either iphone or laptop seem to be less fun than working on the car.

I protected the engine bay with cardboard.

And spent sometime working out how the gearbox support fits. Unfortunately the bolts were missing but rather than wasting the time I had set aside I borrowed some from another pack and sent an email to Derek so I can swap them with the correct ones later.

I then spent ages joining the gearbox to the engine

Time lapse video - I am not sure how to load it.

Having installed the engine I saw this great big hole - straight into the bell housing. A quick phone call to Derek and he has sent the sump protector over that blocks the hole.

Having fitted the gearbox I could not resist the temptation to fit the gear lever.

After the success of the engine it was on to single handedly fitting the diff. It was easier than it sounded.

Saturday 4 April 2015

Handbrake

I have not done much in the last couple of days, to busy with work and family life.

I did manage to get in the garage and torque up my front brake lines having had reassurance from blatchat after my last blog entry.

I have also fitted the hand brake.

Subscribe to:

Posts (Atom)